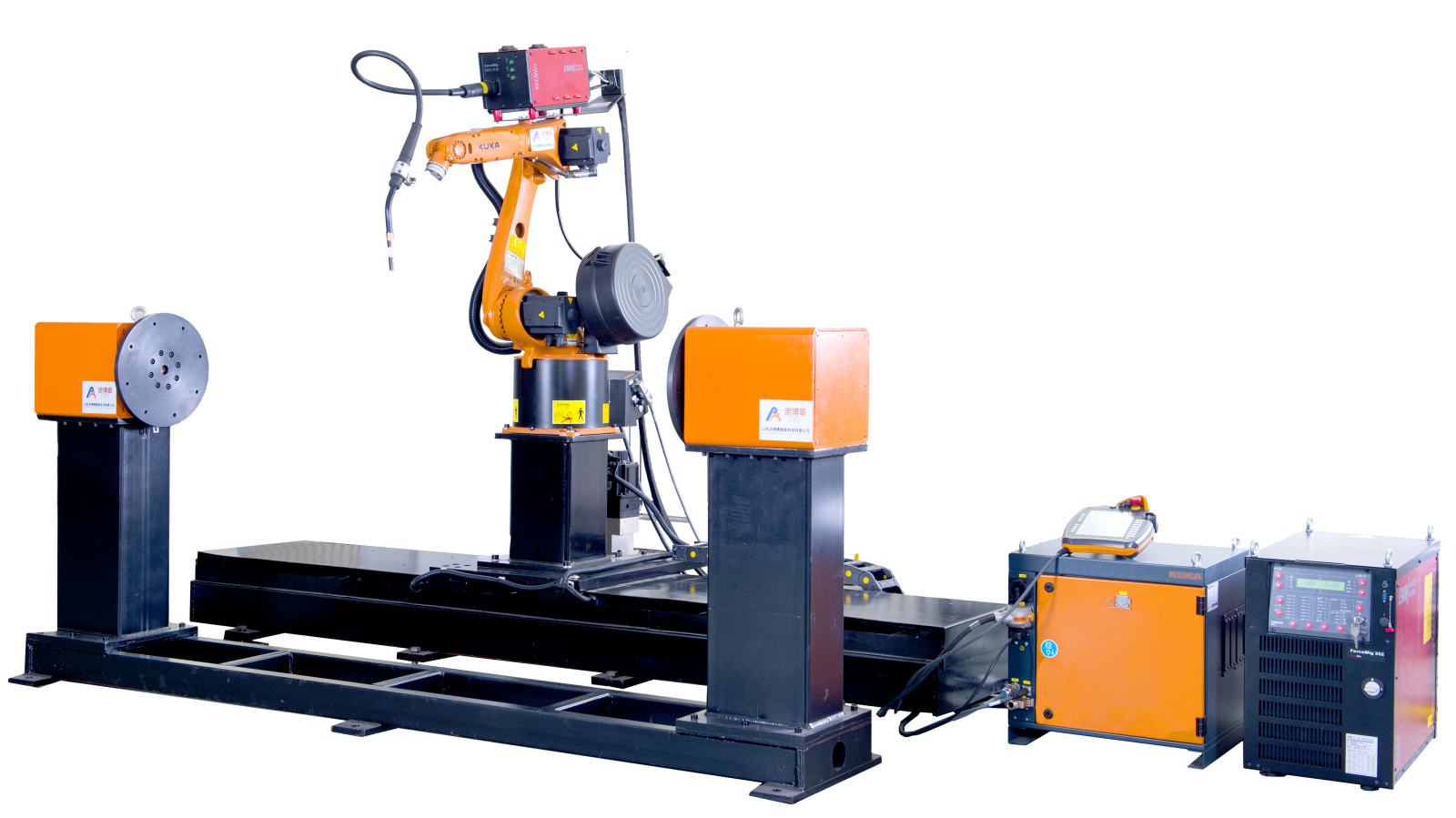

RBT Intelligent welding package adopts KUKA KR5arc R1400 robot

which is wholly manufactured in Germany, also a set of operating and control

systems, EWM high-performance welding machine, BINZEL Mig torch. Pure and high quality, perfect union between

modules, making welding operation

easier, welding production more economical, welding quality more reliable.

1、KUKA KR 5 arc R1400

|

Axis

|

Range of motion

|

speed

|

|

1

|

± 170°

|

218°/s

|

|

2

|

+65° to -180°

|

218°/s

|

|

3

|

+165° to -120°

|

218°/s

|

|

4

|

±185°

|

381°/s

|

|

5

|

±120°

|

314°/s

|

|

6

|

±360°

|

492°/s

|

Rated payload

|

Rated payload

|

5kg

|

|

Supplem.load arm

|

10kg

|

|

Supplem.load link arm

|

0kg

|

|

Supplem.load rotating colum

|

20Kg

|

|

Weight

|

~130kg

|

|

A2 axis working scope

|

1022mm

|

Volume of working envelope

|

9.97m3

|

More powerful, safer, more flexible, and above all more intelligent. The revolutionary concept of the KR C4 provides a firm foundation for the automation of tomorrow. It reduces costs in automation for integration, maintenance and servicing. The long-term efficiency and flexibility of the systems are increased at the same time. For this reason, KUKA has developed a new ground-breaking, clearly-structured system architecture that concentrates on open and powerful data standards. In this architecture, all integrated controllers – from SafetyControl, RobotControl, and MotionControl to LogicControl – have a joint database and infrastructure which they use and share intelligently. For maximum performance, scalability and flexibility. Today and in the future – and not just for KUKA robots.

THE FEATURES AT A GLANCE

Simple to plan, operate and maintain

Continuation of service-proven PC-based control technologies

Quick and easy operation thanks to continued use of familiar operator control concepts

Expansion of the set of commands for more user-friendly path programming

High compatibility with previous programs for the KR C2

Safety, Robot, Logic and MotionControl in a single control system

Real-time communication between the dedicated control processes

Central basic services for maximum data consistency

Seamless integration of safety technology for entirely new fields of application

Integrated software firewall for greater network security

Innovative software functions for optimized energy efficiency

Future-compatible technology platform without proprietary hardware

Multi-core processor support for scalable performance

Fast communication via Gigabit Ethernet

Integrated memory cards for important system data

Designed for 380 – 480 VAC without transformer

New fan concept for optimized energy efficiency

Maintenance-free cooling without filter mats

Highest performance in the smallest possible space

Maximum availability

KUKA smartPAD

Touch screen. Graphics support. Flexible interaction. The more powerful the capabilities of the robots become, the more intuitive user interfaces for operator control of the robots are pushed into the foreground. The new KUKA smartPAD brilliantly demonstrates, on a large, high-resolution, antireflection touch screen, how robots can be operated intuitively.

Operations are presented to the user in a transparent manner by means of intelligent, interactive dialogs. The user always has at his disposal precisely the operator control elements that he actually needs at any given moment. With the aim of focusing attention on what is important, so that users can work more intuitively and thus more easily, quickly and efficiently. Simply smarter in every respect.

THE FEATURES AT A GLANCE

Simple, intuitive operator control via touch panel with context-sensitive floating windows

Separate jog keys for direct control of eight axes / external axes – without switching

Efficient programming with 6D mouse and ergonomic keypad in touch panel

Systematic further development of the tried-and-tested KUKA operator control and programming concept

Only little training required

Direct saving and loading of configurations via USB port on the smartPAD itself

Hot-pluggable. If the smartPAD is not required, it can be simply unplugged.

High screen resolution and generously-sized antireflection display for work that is easy on the eyes

2、EWM welding system from Germany

.Force Mig 352 puls DG

Welding power: S86-005107-XX102

Force Mig Drive Rob wire feeder: S86-004999-00102

3、BINZER welding torch